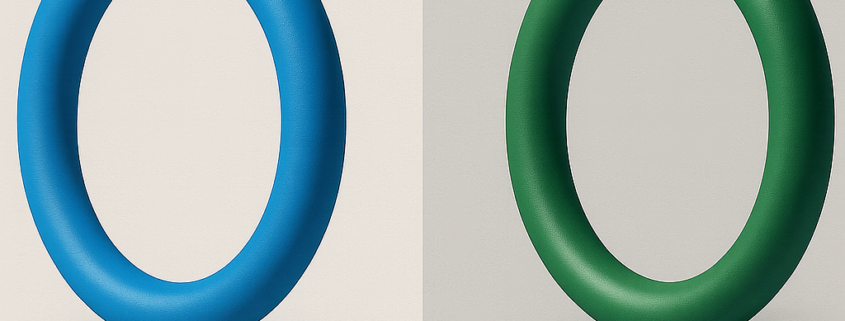

FAQ: NBR vs. Viton® O-rings – Top 10 Questions Answered

When choosing an O-ring for industrial sealing applications, two materials stand out: NBR (nitrile rubber) and Viton® (FKM rubber). In this article, we answer the most frequently asked questions from our customers, helping you decide which material best suits your needs.

In which applications is each material recommended?

NBR O-rings are ideal for applications where oils, greases and standard fuels are present, such as:

-

Hydraulic systems

-

Pneumatic tools

-

Automotive and machinery maintenance

Viton® O-rings, on the other hand, are preferred in more demanding environments with:

-

Aggressive chemicals

-

High temperatures

-

Exposure to ozone and UV

Temperature range: NBR vs. Viton®

-

NBR: Performs well between –30 °C and +100 °C (short-term peaks up to 120 °C).

-

Viton®: Can withstand temperatures from –20 °C to +200 °C, and even higher in some formulations.

Compatibility with oils and fuels

Both materials resist mineral oils and standard fuels, but Viton® offers superior performance with:

-

Aromatic hydrocarbons

-

Synthetic oils

-

Biofuels and aggressive additives

If your application involves modern fuel blends or solvents, Viton® is the safer choice.

Which lasts longer?

Viton® O-rings have greater ageing resistance and retain their properties over time, especially in high-temperature or chemically aggressive environments.

What about price?

NBR is significantly more affordable and is widely used for standard sealing needs. Viton® is more expensive, but necessary for critical or extreme conditions.

Are they interchangeable?

Only under specific conditions. Always check the temperature and chemical compatibility requirements before replacing NBR with Viton® or vice versa.

Are both FDA compliant?

-

NBR: Available in FDA-grade versions for food and beverage applications.

-

Viton®: Some specific grades meet FDA and pharmaceutical regulations.

Which offers better compression set resistance?

Viton® tends to maintain elasticity better under long-term compression and high temperatures.

Which is better for outdoor use?

Viton® resists ozone, sunlight and weathering better than NBR, making it ideal for outdoor or exposed systems.

Still unsure which material to choose?

Contact us today at https://washersandgaskets.com to discuss your needs and receive expert advice.

Manufactures Cusell proudly offers a wide range of industrial gaskets designed to meet the highest standards of quality and environmental responsibility.

For specialised services in plastic injection moulding, visit our new website:

👉 https://www.plasticosinyeccion.com/es/