Klingerit® vs. Klingersil® Gaskets | EN, DIN & ASME Standards

How to Choose Klingerit® and Klingersil® Gaskets According to Industrial Standards (EN, DIN, ASME)

When selecting industrial gaskets, it is not only the composition that matters but also compliance with international standards. Engineers and maintenance managers need to ensure that every gasket installed meets the requirements for safety, tightness, and chemical compatibility.

In this article, we explain the regulatory contexts where Klingerit® and Klingersil® gaskets are accepted or mandatory, and which certifications support their use in highly regulated industries.

Klingerit® Gaskets: Tradition and Applicable Standards

Klingerit® gaskets (based on fibers and rubber) have historically been used in demanding thermal and mechanical applications.

-

Applicable standards: mainly DIN and EN standards for flanges and fittings, especially in steam and pressurized fluid systems.

-

Current limitations: due to environmental restrictions (mineral fibers), their use has been gradually replaced by modern materials such as Klingersil®, except in older facilities or where the regulation still allows it.

-

Context: still used in plants where a full replacement of installations is not feasible and where compatibility with older DIN standards is required.

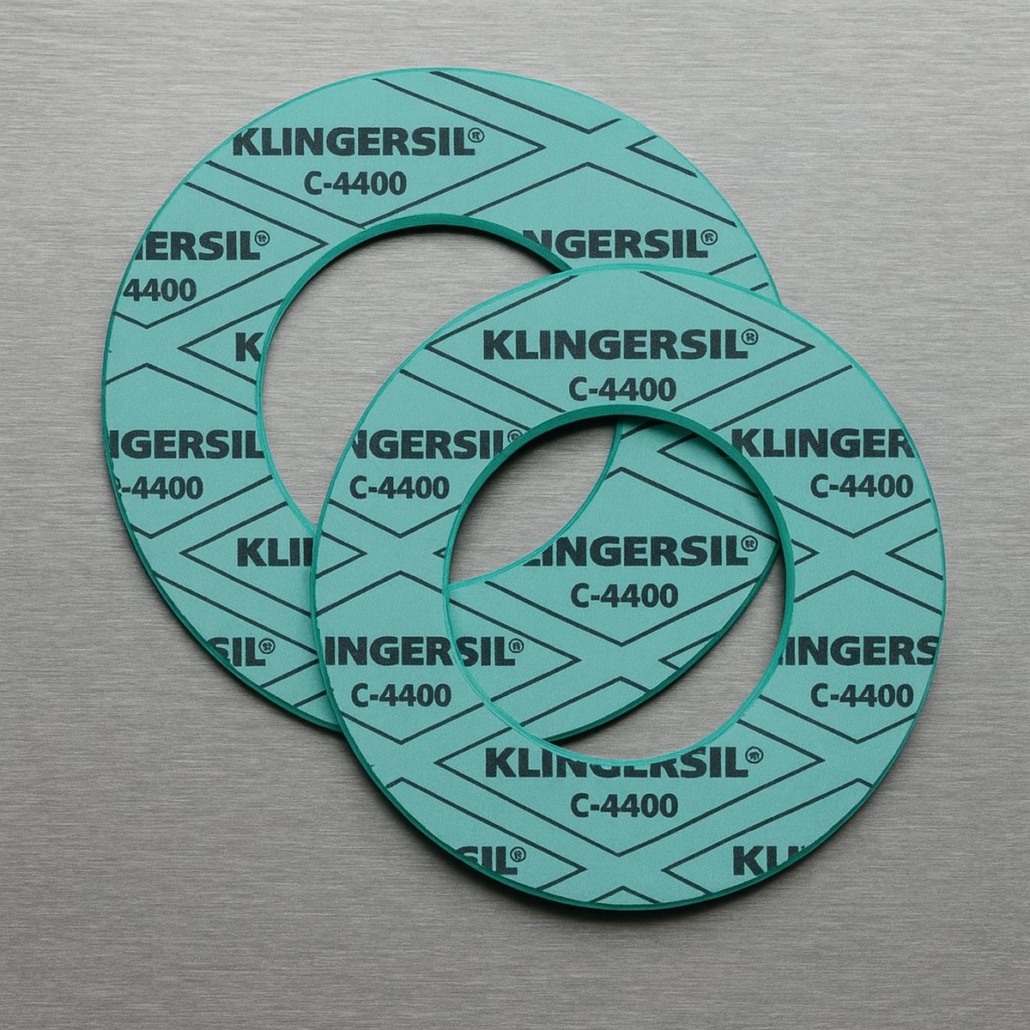

Klingersil® Gaskets: The Current Compliance Standard

Klingersil® gaskets, made from synthetic fibers and high-performance rubber, represent the evolution of Klingerit® and comply with a broad range of international regulations:

-

EN 13555: defines chemical resistance and tightness parameters for flange gaskets.

-

TA Luft / VDI 2440: German leakage certification, mandatory in chemical and petrochemical industries to ensure low fugitive emissions.

-

API / ASME: compliance with American standards for flanges in pressure and temperature applications.

-

DIN / EN 1514: standardized dimensions and tolerances for flat gaskets.

These certifications make Klingersil® the preferred option in:

-

Chemical and petrochemical plants.

-

High-pressure steam and gas installations.

-

Sectors where compliance with strict safety and environmental regulations is essential.

Regulatory Comparison: Klingerit® vs. Klingersil®

| Feature | Klingerit® Gaskets | Klingersil® Gaskets |

|---|---|---|

| Main standards | Classic DIN / EN | EN 13555, TA Luft, API / ASME |

| Typical use | Legacy installations, steam, medium pressure | Chemical processes, high-pressure steam and gas |

| Restrictions | Environmental limitations (fibers) | Fully compliant with current regulations |

| Safety | Adequate in limited contexts | High reliability and certifications |

Conclusion: Compliance as the Key Selection Criterion

When choosing between Klingerit® and Klingersil® gaskets, the key factor is not only mechanical or chemical resistance but also compliance with the required standards.

-

Klingerit® still has a place in legacy installations governed by older regulations or in specific replacements.

- Klingersil®, on the other hand, ensures compatibility with current European and American standards, making it the recommended choice for new projects and highly regulated industries.

Need advice on selecting the right gasket for compliance?

At Manufactures Cusell, we help you choose the certified material that guarantees safety, compliance, and durability in your installation. For more information about gaskets and seals in compressed fiber, please visit our product section